ANALISIS MIKROSTRUKTUR MATERIAL MAGNETIK BERBASIS Nd-Fe–B DAN Sm–Co UNTUK APPLIKASI MAGNET PERMANEN HIBRID

DOI: http://dx.doi.org/10.17146/urania.2011.17.2.733

Sari

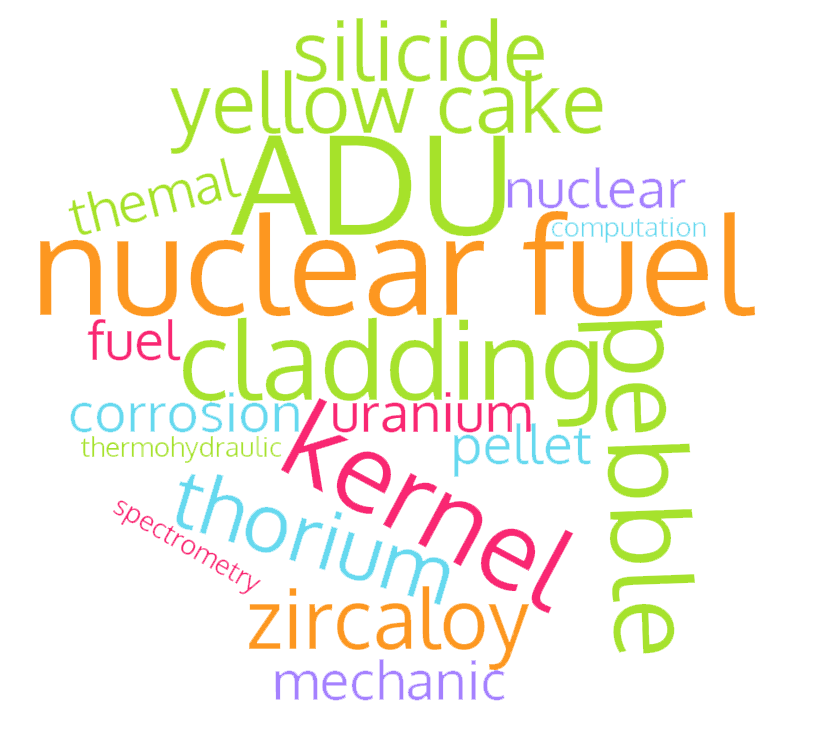

Telah dilakukan preparasi, kajian dan pengamatan mikrostruktur sampel magnet hibrid SmCo5 – Nd12Fe82B6 setelah melalui proses preparasi teknik metalurgi serbuk. Dengan mensubsitusi unsur Dy ke dalam Nd-Fe-B maka terbentuk ingot paduan fasa Nd12-xDyx Fe82B6 (at.%) dengan x = 0, 1, 2, 6 dan 9, selanjutnya ingot di mill untuk menghasilkan serbuk halus (Nd,Dy)-Fe-B dengan ukuran partikel 20-40 mm. Serbuk Sm-Co dan (Nd,Dy)-Fe-B dicampur dengan perbandingan 80:20 (wt%). Material tersebut dipadatkan dalam cetakan kemudian diberi siklus perlakuan panas dan sampel yang sangat padat dihasilkan. Telah dihasilkan mikrostruktur material hibrid (Pr,Nd,Sm,Dy)2(Fe,Co)14B, (Pr,Nd,Sm,Dy)Co5 setelah tahapan sinter pada temperatur 1150 oC dan anil pada temperatur 850 oC selama 51/2 jam dan diikuti pendinginan cepat kedalam air. Juga telah diamati bahwa ”fasa bingkai” mempunyai tipe 1-5 dan 2-14-1 disamping fasa utama 2-14-1 dan 1-5 dalam material hibrid seperti ditunjukkan oleh SEM-EDS, XRF dan XRD. Struktur mikro tersebut sepertinya berpenampilan ”unik” karena berbeda dengan struktur mikro material magnet konvensional yang berbasiskan Nd-Fe-B atau Sm-Co. Kesimpulan dari penelitian ini adalah bahwa hibridisasi dua fasa magnetik permanen yang berbeda telah memberikan informasi baru yaitu telah dihasilkannya struktur mikro yang ”unik” walaupun fasa-fasa magnetik 1-5 dan 2-14-1 masih tetap dipertahankan sebagai fasa-fasa utama dalam material material hibrid.

The preparation, investigation and observation of microstructure of the SmCo5 – Nd12Fe82B6 hybride magnetics sample which after preparation processing by powder metallurgy technique have been done. The element of Dy was substituted into Nd-Fe-B to produces Nd12-x Dyx Fe82B6 (at%) alloys with x = 0, 1, 2, 6 and 9. The ingots were further ball milled to produce fine powders of (Nd,Dy)-Fe-B in the size range of 20-40 µm. Both kinds of powders Sm-Co and Nd-Fe-B base were then mixed with ratio 80:20 (wt%). This materials were compacted in a die, then fully dense compacting samples were obtained after the application of designed heat treatments. It was found that microstructure for hybrid materials consisted of (Pr,Nd,Sm,Dy)2(Fe,Co)14B, (Pr,Nd,Sm,Dy)Co5 obtained after a sintering step at temperature 1150 oC and annealed at a temperature of 850 oC for 51/2 hours and followed by quenching into water. It was also observed that a ”frame phase” of 1-5 and 2-14-1 types in addition to the main phase of 2-14-1 and 1-5 in hybride materials as shown by SEM-EDS, XRF and XRD. This kind of microstructure is assumed unique because different with conventional microstructure of sintered Nd-Fe-B or Sm-Co based materials. The conclusion of the current study is that hybridization of two different hard magnetic phases have given new information in that it has produced unique microstructures while the magnetic phases of 1-5 and 2-14-1 still remain as the main phases in hybride materials.

Keyword: Nd-Fe-B, Sm-Co, permanent magnets, sintered magnets, magnetic properties.

Teks Lengkap:

PDFRefbacks

- Saat ini tidak ada refbacks.

Penerbit: Pusat Riset Teknologi Bahan Nuklir dan Limbah Radioaktif

Diindeks oleh: