THE CONCEPTUAL DESIGN FOR LIQUID EFFLUENT TREATMENT OF UO2 KERNEL FABRICATION

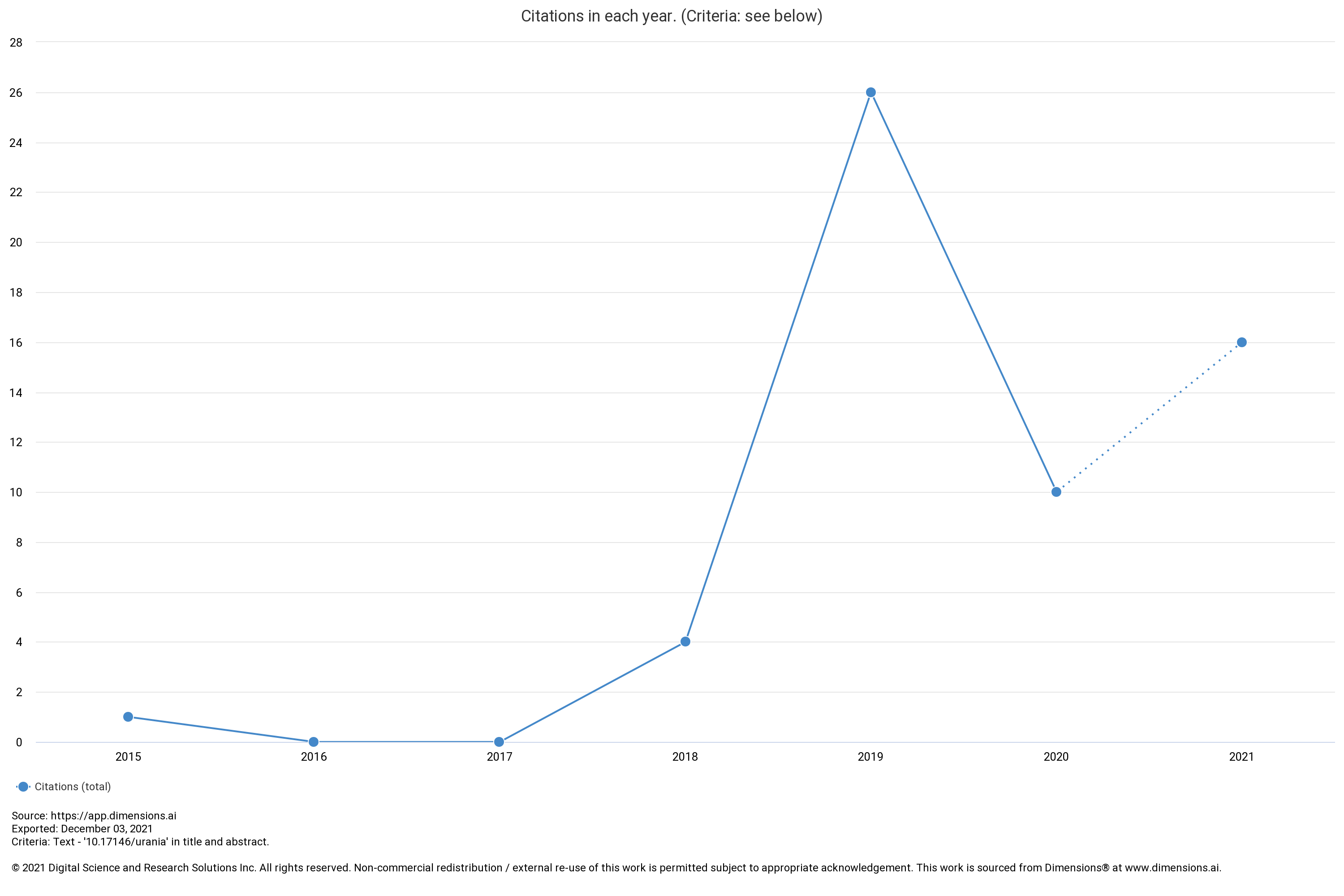

DOI: http://dx.doi.org/10.17146/urania.2020.26.2.5881

Sari

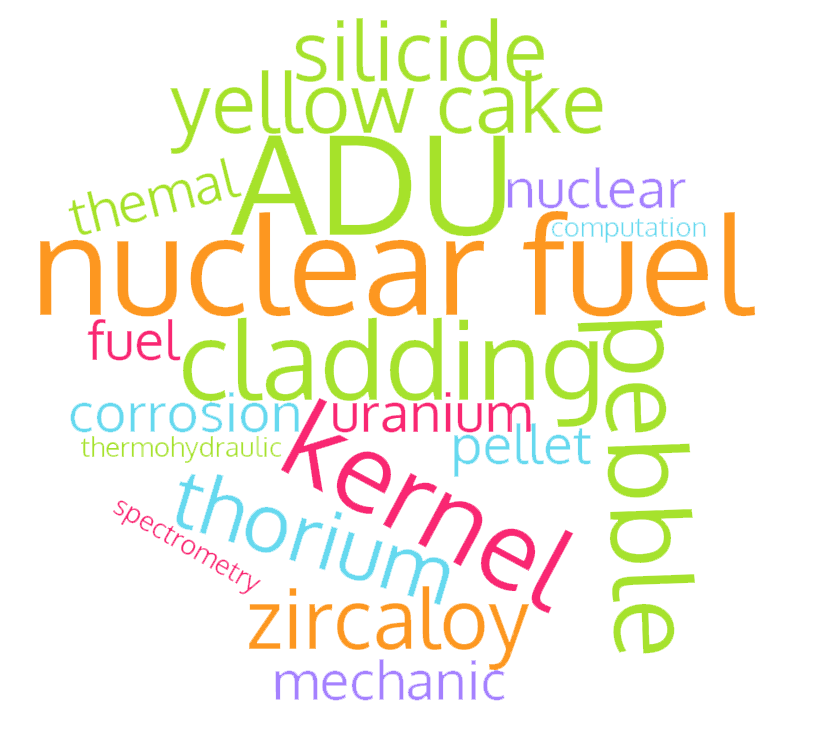

THE CONCEPTUAL DESIGN FOR LIQUID EFFLUENT TREATMENT OF UO2 KERNEL FABRICATION. The pebble fuel for HTGR is prepared through fabrication of UO2 kernel, coated particle and spherical element fuel. In the fabrication of UO2 kernel by external gelation method, a multicomponent of liquid effluent is generated. Therefore, the liquid effluent is required to be treated for safety reason before disposed to waste storage. In this paper, the conceptual design for the liquid effluent treatment of UO2 kernel fabrication is performed with the simulation process using CHEMCAD software. CHEMCAD is a software that can be utilized for chemical process design. The results showed that the proposed conceptual design is able to separate valuable components: isopropyl alcohol (IPA) and tetrahydrofurfuryl alcohol (THFA). The flowrate of IPA product is

5.28 kg/h with purity of 0.99 in mass fraction and the flowrate of THFA product is 1.01 kg/h with purity of 0.99 in mass fraction.

Teks Lengkap:

PDFRefbacks

- Saat ini tidak ada refbacks.

Penerbit: Pusat Riset Teknologi Bahan Nuklir dan Limbah Radioaktif

Diindeks oleh: